TechRadar Verdict

The Form 2 stands alone both in terms of price and ability. Print quality and resin mean that you can build almost anything but the price and SLA technology will not suit everyone.

Pros

- +

High quality prints

- +

Practical resins

- +

Easy to extract models

Cons

- -

Printing times are slow

- -

Messy when cleaning up prints

- -

Expensive compared with FFM printers

Why you can trust TechRadar

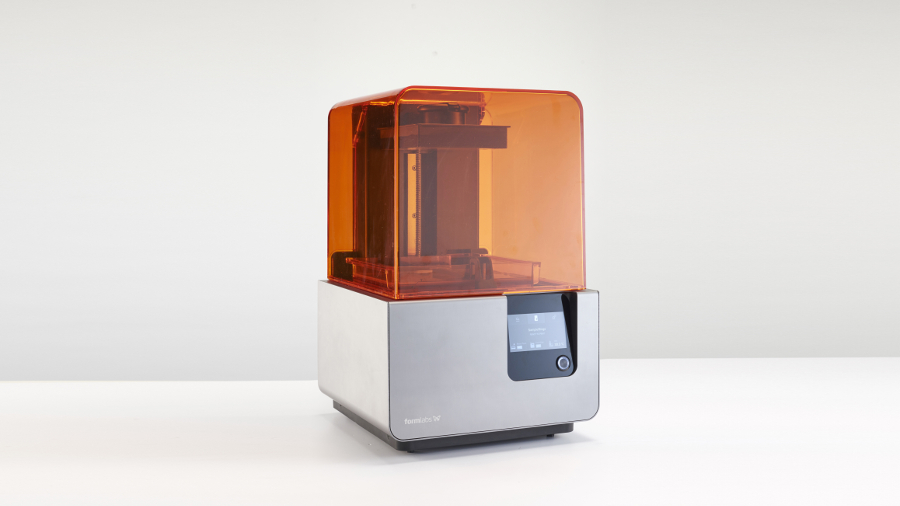

FormLabs is established as the leading manufacturer of Stereolithography (SLA) 3D printers. SLA printers use a resin rather than a filament that hardens when exposed to ultraviolet light.

Although the technology of the SLA printers is quite different to that used by fused filament modelling (FFM) printers, the basic principle – building layer upon layer to create the print – is the same.

At £3,120 (around $4,580, or AU$6,350), the Form 2's price is at the top-end of the consumer market and the basic cost is almost double that of the high-end FFM printers such as the Ultimaker 2.

The design differences between an SLA and FFM printer are instantly obvious. The main build platform of an SLA printer is suspended over a resin tank so as the print is mapped out by the laser, the print is built bottom-down rather than bottom-up as with an FFM.

The whole process looks futuristic, as layer upon layer is being mapped by the laser and the laser's path is set in the resin. As the print progresses and the build plate slowly lifts the print slowly emerges from the resin.

Unlike FFM printers that use infill to alter the amount of filament that is being used inside the solid parts of the print, an SLA printer will always print solid, and this ultimately makes the models stronger but does mean that more material is used.

Getting started

On unboxing the printer the initial setup process is relatively straightforward. Compared with other SLA printers such as the XYZ Nobel 1.0 the design is more refined as there are no feed pipes between the resin tank or bottle that could lead to spillage.

The first item that needs to be installed is the resin tank and this simply clips into the base of the printer. It's a good idea to have a tank for each resin that you use, although each additional tank is quite expensive at around £52 ($59 over in the US, which is around AU$82).

Once the resin tank is in place a small wiper is clipped onto the relevant part in the printer's base. This wipes through the tank after each layer is built to ensure that the resin is evenly spread and helps prevent the build-up of solidified resin as the beam passes through the tank.

The tank itself sits over a glass panel beneath which is the laser. It's important during the setup and when you switch tanks that the base isn't touched as this could affect the beam and the quality of the print.

When you swap out the resin for another colour or type the tank can be quickly removed and comes with a loose fitting top that enables you to neatly store it away for later use.

Leaving a tank of resin for more than two months isn't a good idea, and you also shouldn't return the resin to the bottle after use as this can cause contamination.

The resin arrives ready to go in a specially shaped bottle that is dropped into the back of the printer. Once in place the resin automatically pours into the resin tank as the printer is primed before use.

The Form 2 is fully Wi-Fi compatible so when it comes to printing you have the choice of tethering the printer to your computer by means of a USB, network cable or via Wi-Fi.

Setting up the Wi-Fi connection using the small interface is quick and easy enough and once done you can send prints through to the printer from the software without the need to reconnect physically.

The software handles the majority of the printer's settings and enables you to quickly select quality as well as the material type.